COB FOB high cri 24v led strip light

1. Technical parameters of Flexible LED Strip Light

2. The Characteristics of 24V LED Flex Strip Light

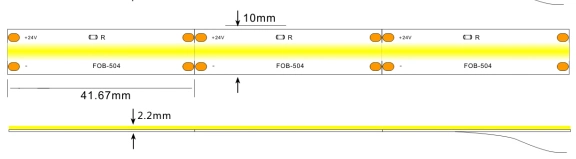

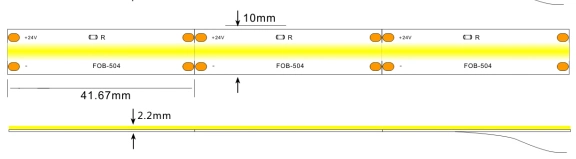

3. Dimension of 24V SMD LED Strip Light

4. Max Value(TA=25ºC) of 24v LED Strip Light

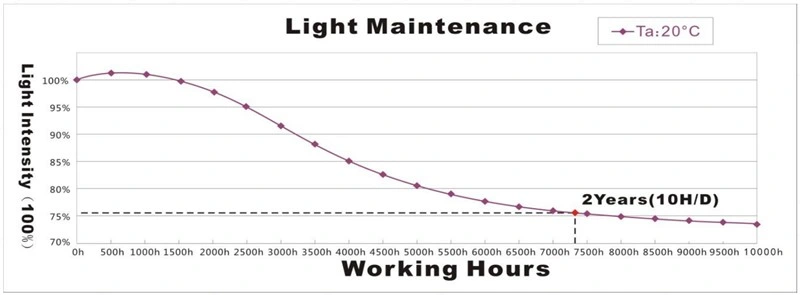

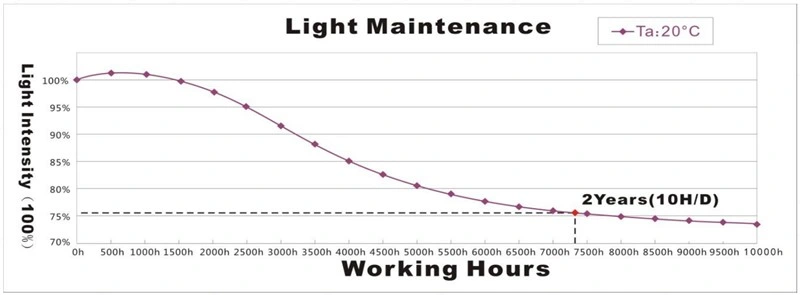

5. Light decay Graph of FOB Waterproof LED Strip Light

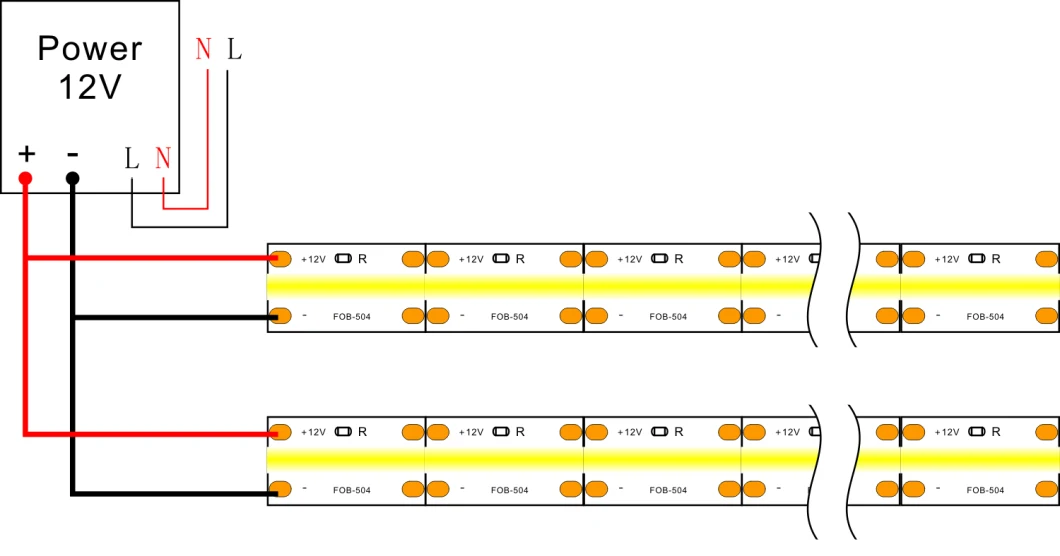

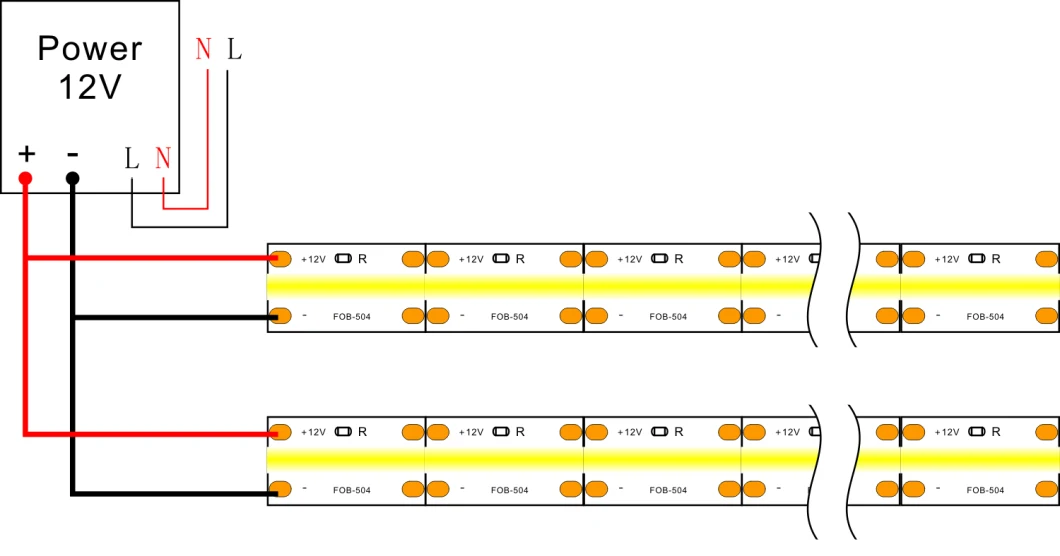

6.Connection diagram of LED Strip Lamp

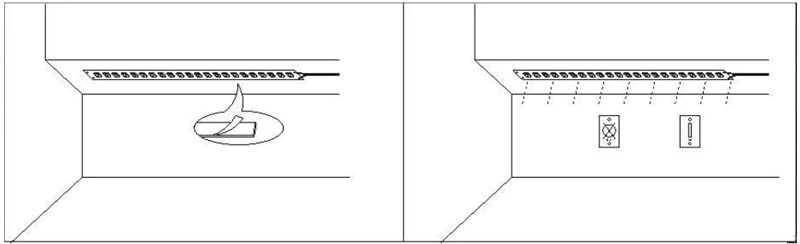

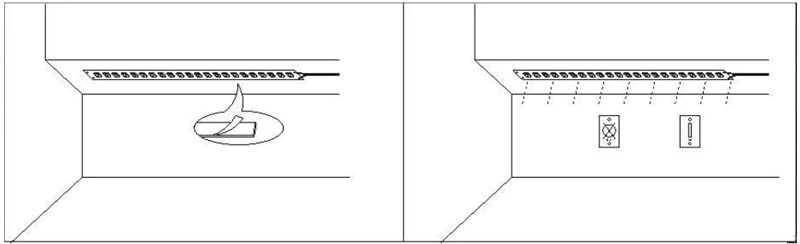

7.Installation drawing of Flexible LED Strip

8. Installation instruction of LED Strip Lamp

9. Installation requirement of SMD LED Strips

Connection diagramConnection diagram

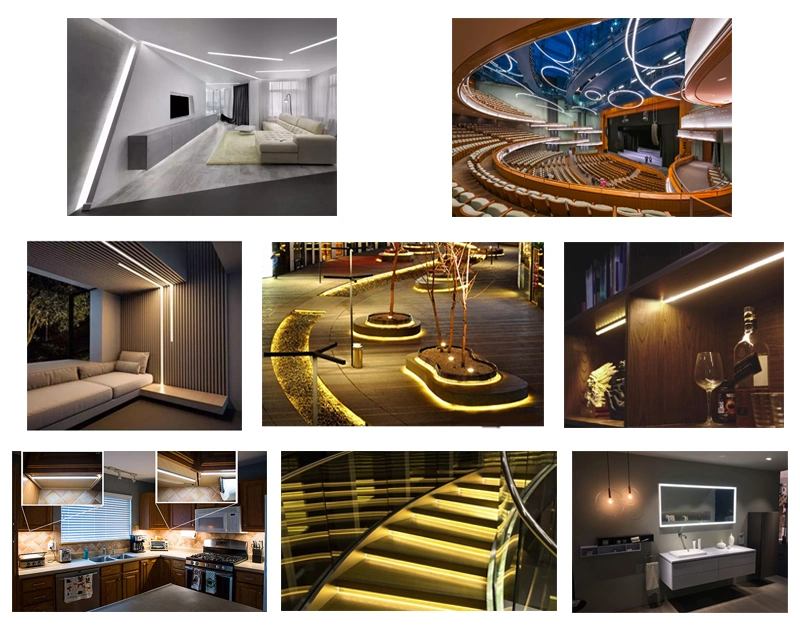

10. Application of 24 Volt LED Strip Lighting

**(1) Letter signage backlight;

**(2) Building Decoration;

**(3) Auditorium walkway lighting;

**(4) Advertising signs, light box lightinge;

**(5) Landscape decoration;

Looking forward your inquiry!

1. Technical parameters of Flexible LED Strip Light

| Model-504LED/M | Color | LEDs Qty. | LEDs Type | Beam angle(°C) | Voltage (DC) | RA | Power (W/M) | LM/W | Min. cut/mm |

VGD-FOB-24V-D504 | 2700K | 504 | FOB (COB) | 180° | 24V | ≥80 ≥90 | 14W | 100 | 41.67 |

VGD-FOB-24V-D504 | 3000K | 14W | 41.67 | ||||||

VGD-FOB-24V-D504 | 4000K | 14W | 41.67 | ||||||

VGD-FOB-24V-D504 | 6000K | 14W | 41.67 | ||||||

VGD-FOB-24V-D504 | R | 14W | 15 | 41.67 | |||||

VGD-FOB-24V-D504 | G | 14W | 80 | 41.67 | |||||

| VGD-FOB-24V-D504 | B | 14W | 23 | 41.67 |

2. The Characteristics of 24V LED Flex Strip Light

| (1) Adopt brand LED chip,high brightness,low light decay,lifespan more than 25000 hours; |

| (2) Color:2700K,3000K,4000K,6000K ,red,green,blue,yellow; |

| (3)All of materials are accord with RoHS standards; |

| (4) Easy to install and preserve;can be bent freely; with 3M adhesive tape on the backside; |

| (5) High color efficiency, uniform illumination; |

| (6) Beam angle 180°; |

| (7) Multiple protection levels are optional: IP20--- non-waterproof; IP64--- Drop silicone; IP67--- silicone tube; IP67--- extrusion; IP68 -- Silicone tube + Silicone inside. |

3. Dimension of 24V SMD LED Strip Light

4. Max Value(TA=25ºC) of 24v LED Strip Light

| Parameter | Symbol | Max Value |

| Forward Current | IF | 750mA |

| Power | PD | 14W |

| Antistatic | ESD | >2000V |

| Working temperature | Topr | -25 - 40ºC |

| Storage temperature | Tstg | -40 - 60ºC |

5. Light decay Graph of FOB Waterproof LED Strip Light

6.Connection diagram of LED Strip Lamp

7.Installation drawing of Flexible LED Strip

8. Installation instruction of LED Strip Lamp

| (1) Please choose correct power supply for led strips. The total power of the led strip is about 80% of the power supply, and it cannot be fully loaded to ensure that the power supply works at the correct and stable voltage. |

| (2) We suggest 5 meters/roll for the led strip.If it is over 5 meters length, the brightness of LED will vary greatly. If the customer can accept the case, length can be made over 5 meters/roll. |

| (3) Adhesive tape on the back side of the strip,with its superior adhesive and weather resistance, and can be connected to any transparent glass, metal and plastic surface. But on some certain surfaces, such as cloth, wood, will affect its function and durability.Please test the adhesion of the led strip before installation. |

| (4) Please pay special attention to the minimum bending diameter of the led strip is 60mm, so as to avoid direct or indirect damage to FPC and components on FPC, which may lead to damages of the strip . |

| (5) In order to ensure waterproof and anti-corrosive function , after the power line is screwed into the connector, it is recommended to inject the connector with a single component of silica gel (or neutral glass glue, or waterproof grease) and cover the exposed copper wire of the power line for protection. |

| (6) The non-waterproof led strip shall not be completely exposed for outdoor use. Do not touch or install the strip when it is charged. |

| (7)It is recommended to use switch power supply that has passed relevant safety regulations (with short circuit protection, over voltage protection and over current protection). |

9. Installation requirement of SMD LED Strips

| (1) | Pay attention to handling with care; |

| (2) | Don't install the product in corrosion, flammable and explosive places; |

| (3) | It is strictly prohibited to use any acidic or alkaline adhesives to fix the product. Neutral adhesives are required; |

| (4) | In order to avoid the danger of electric shock, please cut off the power supply during process of installation, debugging and moving; |

| (5) | Ensure correct and reliable connection of all joints; |

| (6) | The product need anti-corrosion environment, such as, avoiding damp, water drop or other adverse elements. |

| (7) | The LED strip and accessories can't be squeezed or folded; |

| (8) | PCB conductive parts can't be damaged when installation; |

| (9) | Installation must conform to electrical safety standard. The LED strip can only be installed by Professionals; |

| (10) | Ensure power supply transform operating load with transformer; |

| (11) | When install on metal or conductor surface, insulation protection need to be provided to the contact area; |

| (12) | Observe positive and negative polarity, ensure correct connection to avoid damaging LED strip; |

| (13) | When installation, please prevent static electricity; |

| (14) | If you have any questions about this product, please consult our salesman. |

Connection diagramConnection diagram

10. Application of 24 Volt LED Strip Lighting

**(1) Letter signage backlight;

**(2) Building Decoration;

**(3) Auditorium walkway lighting;

**(4) Advertising signs, light box lightinge;

**(5) Landscape decoration;

Looking forward your inquiry!